Kraanhaak materiaal graad vergelyking

2025-09-17

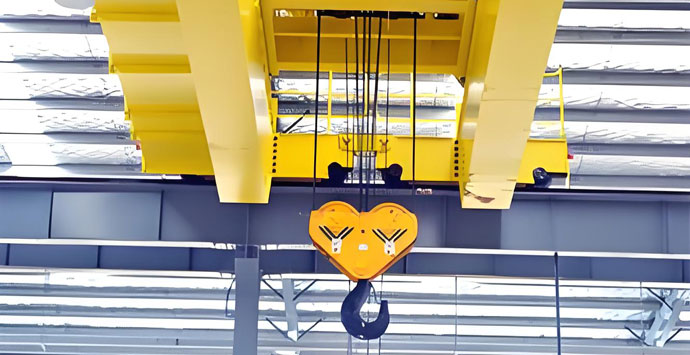

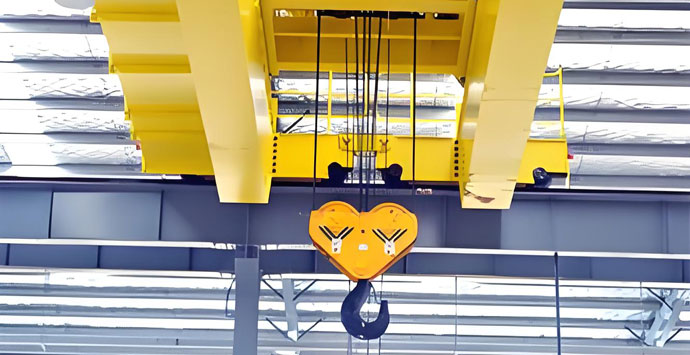

Wanneer dit kom by swaar optel, alle oë is op die hyskraan—sy indrukwekkende hoogte, sy kragtige hysbak, sy grasieuse beweging. Maar die ware onbesonge held, die kritieke punt waar al daardie krag saamvloei, is 'n relatief klein komponent: die hyskraanhaak. Hierdie nederige stuk metaal dra die hele gewig van die vrag, en die mislukking daarvan is nie 'n opsie nie.

Die integriteit van 'n hyskraanhaak is amper heeltemal afhanklik van die materiaal waaruit dit gesmee is. Die keuse van die regte graad gaan nie net oor krag nie; dit gaan oor taaiheid, rekbaarheid, en weerstand teen moegheid. In hierdie pos, ons sal die algemene materiaalgrade wat vir kraanhake gebruik word, uiteensit en jou help om te verstaan wat elkeen geskik maak vir sy spesifieke rol.

Waarom Materiële Keuse van kritieke belang is

'n Hyskraanhaak word aan geweldige en komplekse spannings onderwerp - hoofsaaklik spanning, maar ook buiging en potensiële sylading. Die ideale materiaal moet 'n kombinasie van besit:

- 1. Hoë opbrengssterkte: Om permanente vervorming onder las te weerstaan.

- 2. Hoë treksterkte: Om breking te weerstaan.

- 3. Goeie rekbaarheid: Om effens te vervorm (rek) voor breek, visuele waarskuwing verskaf.

- 4. Uitstekende taaiheid: Om energie te absorbeer en skoklading en impak te weerstaan.

- 5. Moegheidsweerstand: Om herhaalde lassiklusse te weerstaan sonder om krake te ontwikkel.

Nou, kom ons vergelyk die mees algemene materiaal grade.

Koolstofstaal (Bv., A36 of Ekwivalent)

- 1. Oorsig: Dit is 'n algemene doel, lae-koolstof staal. Dit is smeebaar, relatief goedkoop, en maklik om te vervaardig.

- 2. Tipiese gebruik: Ligte toepassings. Jy kan hake wat van hierdie grade gemaak is op kleiner werkswinkelhyskrane vind, swaai hyskrane, of vir baie lae-kapasiteit vragte.

- 3. Voordele: Koste-effektief, goeie sweisbaarheid.

- 4. Nadele: Laer sterkte en taaiheid in vergelyking met legeringsstaal. Nie geskik vir swaar vragte nie, dinamiese opheffing, of koue omgewings waar dit bros kan word.

- 5. Uitspraak: 'n Basiese keuse vir nie-kritiese, lae-kapasiteit opheffing.

Hoë-sterkte lae-legering staal (HSLA) (Bv., ASTM A572 Graad 50)

- 1. Oorsig: Hierdie graad bied 'n aansienlike stap op vanaf koolstofstaal. Deur klein hoeveelhede legeringselemente soos columbium-vanadium by te voeg, dit behaal hoër opbrengs- en treksterkte terwyl dit goeie vormbaarheid behou.

- 2. Tipiese gebruik: Medium-diens hyskraanhake en ander strukturele komponente. 'n Baie algemene en veelsydige materiaal.

- 3. Voordele: Uitstekende sterkte-tot-gewig verhouding, beter weerstand teen atmosferiese korrosie as koolstofstaal, en goeie sweisbaarheid.

- 4. Nadele: Terwyl sterker, its toughness and fatigue resistance may still be outperformed by more specialized grades.

- 5. Uitspraak: The reliable workhorse for a wide range of general industrial lifting applications.

Allooi staal (Bv., ASTM A508 / A508 Gr.4N)

- 1. Oorsig: This is where we enter the realm of high-performance crane hooks. Alloy steels like A508 are quenched and tempered to achieve an exceptional combination of very high strength and superior toughness.

- 2. Tipiese gebruik: Heavy-duty and high-capacity hooks for overhead cranes, toring hyskrane, en mobiele hyskrane. This is the industry standard for serious lifting.

- 3. Voordele: Exceptional yield and tensile strength, outstanding impact toughness (even at low temperatures), and excellent fatigue life. It is designed to bend, not break.

- 4. Nadele: More expensive than carbon or HSLA steels. Requires precise heat treatment during manufacturing.

- 5. Uitspraak: The premium choice for safety-critical, hoë kapasiteit, and high-cycle applications.

Vlekvrye staal (Bv., 316 of 410 Vlekvry)

- 1. Oorsig: Die primêre voordeel van vlekvrye staal is sy uitsonderlike korrosiebestandheid.

- 2. Tipiese gebruik: Gespesialiseerde omgewings waar vog en chemikalieë 'n konstante bedreiging is. Dink aan mariene toepassings, chemiese aanlegte, voedsel- en drankverwerking, en farmaseutiese produkte.

- 3. Voordele: Uitstekende weerstand teen korrosie, higiëniese eienskappe (maklik om skoon te maak).

- 4. Nadele: Het oor die algemeen 'n laer sterkte as 'n ekwivalente grootte legeringstaalhaak. Aansienlik duurder. Die moegheidssterkte kan ook laer wees.

- 5. Uitspraak: Nie gekies vir sy sterkte nie, maar vir sy weerstand teen korrosiewe omgewings waar 'n standaard staalhaak vinnig sou verneder en onveilig sou word.

Vergelykingstabel in 'n oogopslag

| Materiële graad |

Tipiese gebruiksgeval |

Sleutel eienskappe |

Beste vir |

| Koolstofstaal (A36) |

Ligte-diens |

Lae koste, goeie sweisbaarheid |

Nie-krities, lae-kapasiteit hysbakke |

| HSLA Staal (A572 Gr. 50) |

Medium-diens |

Goeie sterkte-tot-gewig verhouding |

Algemene industriële toepassings |

| Allooi staal (A508) |

Swaardiens |

Hoë sterkte & superieure taaiheid |

Hoë kapasiteit, veiligheidskritiese hysbakke |

| Vlekvrye staal (316/410) |

Korrosiewe omgewings |

Uitstekende weerstand teen korrosie |

Marine, chemiese, kos & drankbedrywe |

Hoe om te kies: Dit gaan nie net oor die graad nie

Terwyl materiaalgraad die belangrikste is, dit is net een deel van die vergelyking. Die vervaardigingsproses - spesifiek smee en hittebehandeling - is ewe belangrik.

- 1. Smee: Gesmede kraanhake is sterker as dié wat uit plaat gegiet of gesny is. Smeedwerk bring die metaal se korrelstruktuur in lyn met die vorm van die haak, die skep van 'n deel wat inherent sterker en meer weerstand teen impak is.

- 2. Hittebehandeling (Uitblus & Tempering): Hierdie proses beheer presies die hardheid, sterkte, en, belangrikste, die taaiheid van die finale produk. 'n Behoorlik hittebehandelde haak het die perfekte balans om sterk genoeg te wees om die vrag te hou, maar tog taai genoeg om te vervorm onder uiterste oorlading.

Soek altyd hake wat volgens relevante standaarde gesertifiseer is (Soos ASME B30.10), wat die materiaal beheer, ontwerp, vervaardiging, en toetsprosesse.

Daar is geen een-grootte-pas-almal-antwoord nie. Die "beste" kraanhaakmateriaal is die een wat geskik is vir die doel:

- 1. Vir standaard fabriek opheffing, 'n A572- of A508-haak is tipies.

- 2. Vir die mees veeleisende, swaar siklus, en hysbakke met die hoogste kapasiteit, legeringstaal soos A508 is die onomwonde keuse vir maksimum veiligheid.

- 3. Moet nooit 'n kompromie aangaan met 'n koolstofstaalhaak vir 'n veeleisende toepassing nie, en kies net vlekvrye staal wanneer die omgewing dit vereis.

Raadpleeg altyd die vervaardiger se spesifikasies en maak seker dat jou haak die regte sertifisering vir jou toepassing het. Onthou, die haak is die finaal, kritieke skakel in jou opheffingsketting—om in die regte materiaal te belê, is investering in veiligheid.

Nuutste kommentaar