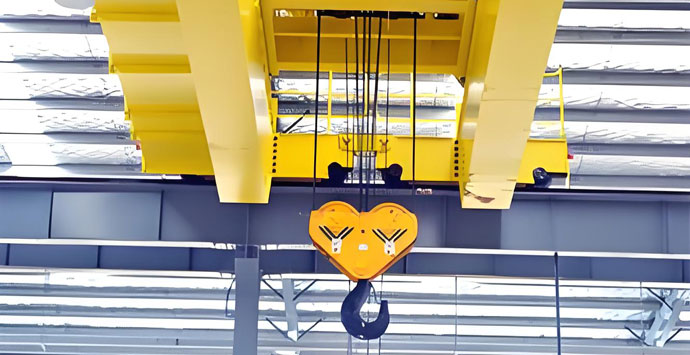

Kraanhake is kritieke draende komponente in hysstelsels, ontwerp om swaar vragte veilig en doeltreffend te dra. Nietemin, soos enige meganiese deel wat aan herhaalde spanning onderwerp word, hyskraanhake kan misluk as dit nie behoorlik ontwerp is nie, gebruik word, en onderhou. N kraanhaak mislukking analise verslag is noodsaaklik om die oorsaak van sulke mislukkings te identifiseer en toekomstige voorvalle te voorkom.

Kraanhaak mislukkings kan lei tot ernstige veiligheidsgevare, operasionele stilstand, en finansiële verliese. Die uitvoer van 'n deeglike mislukkingsanalise help om:

1. Identifiseer die presiese oorsaak van die mislukking

2. Verbeter toekomstige haakontwerp en vervaardigingsprosesse

3. Verbeter veiligheidsprotokolle vir opheffingsoperasies

4. Voldoen aan industrieveiligheidstandaarde en wetlike vereistes

Gebaseer op industrie gevallestudies en ingenieursondersoeke, die volgende is die mees algemene oorsake:

1. Materiële defekte – insluitings, porositeit, of onbehoorlike hittebehandeling kan die haak verswak.

2. Oorlading – Oorskry die veilige werkslas (Swl) lei tot plastiese vervorming of breuk.

3. Moegheidskrake - Herhaalde sikliese laai met verloop van tyd kan mikrokrake inisieer, uiteindelik lei tot katastrofiese mislukking.

4. Korrosie – Blootstelling aan moeilike omgewings kan materiaalsterkte verminder.

5. Onbehoorlike instandhouding – Gebrek aan gereelde inspeksie en smering versnel slytasie en skade.

'n Professionele mislukkingsanalise behels tipies die volgende stadiums:

1. Visuele inspeksie

Aanvanklike waarneming van die gebreekte haak, insluitend fraktuuroppervlakpatrone, vervorming, en dra merke.

2. Dimensionele meting

Kontroleer die haak se keelopening, dra, en dimensionele veranderinge teenoor vervaardigerspesifikasies.

3. Materiële toetsing

Chemiese samestelling-analise om voldoening aan standaarde te verifieer.

Hardheidtoetsing om hittebehandelingskwaliteit te bepaal.

4. Nie-vernietigende toetsing (Ndt)

Metodes soos magnetiese deeltjietoetsing (MPT) of ultrasoniese toetsing (UT) word gebruik om interne krake op te spoor sonder om die onderdeel te beskadig.

5. Fraktografie & Mikroskopiese ondersoek

Skandeer-elektronmikroskopie (WATTER) of optiese mikroskopie om fraktuuroppervlaktes te bestudeer en moegheidsstrepe of brosbreukkenmerke te identifiseer.

6. Laai geskiedenisoorsig

Gaan instandhoudingslogboeke na, operasionele rekords, en hysiklusse om laaipatrone en potensiële oorladingsvoorvalle te bepaal.

7. Grondoorsaakbepaling

Kombineer toetsresultate, materiële data, en operasionele geskiedenis om te bepaal of mislukking te wyte was aan ontwerpfout, vervaardigingsfout, onbehoorlike gebruik, of onvoldoende onderhoud.

’n Gedetailleerde ontledingsverslag van hyskraanhaak-mislukkings identifiseer nie net die oorsaak nie, maar verskaf ook uitvoerbare aanbevelings, soos:

1. Die gebruik van hoër-graad legeringstaal met behoorlike hittebehandeling.

2. Implementering van streng lasmoniteringstelsels.

3. Doen gereelde NDT-inspeksies.

4. Opleiding van operateurs oor korrekte opheffingspraktyke.

5. Die toepassing van beskermende bedekkings vir weerstand teen korrosie.

N hyskraanhaak mislukking is nooit net 'n meganiese probleem nie - dit is 'n ernstige veiligheidsprobleem. Deur die uitvoer van 'n omvattende kraanhaak mislukking analise verslag, nywerhede toekomstige ongelukke kan voorkom, operasionele veiligheid te verbeter, en verseker voldoening aan hystoerustingstandaarde. Die koste van 'n professionele ontleding is weglaatbaar in vergelyking met die potensiële gevolge van 'n ander mislukking.

Ons waardeer u terugvoer! Vul die onderstaande vorm in sodat ons ons dienste by u spesifieke behoeftes kan aanpas.

Nuutste kommentaar