Jak obliczyć udźwig haka do podnoszenia?

2025-07-24

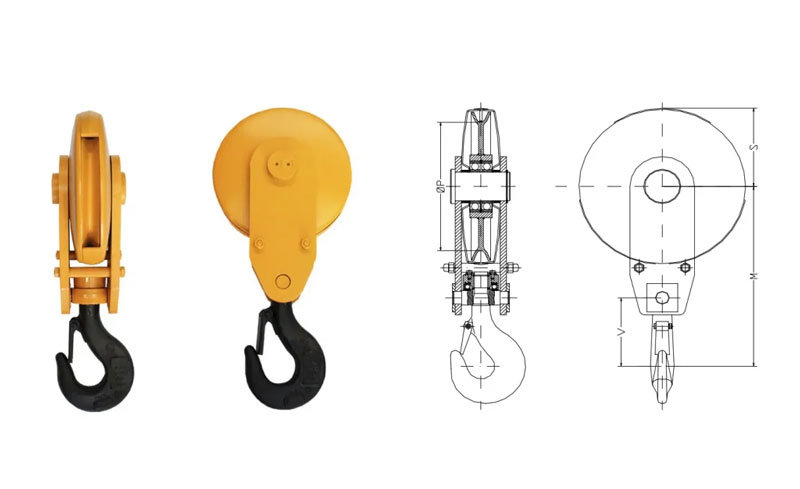

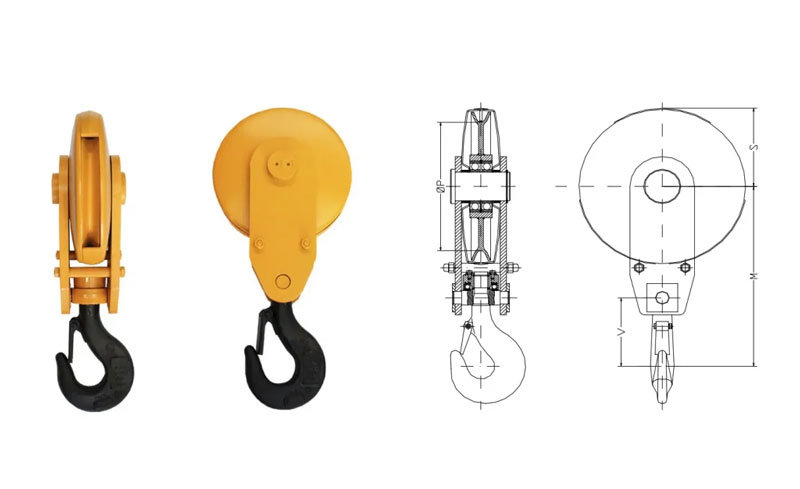

Lifting hooks are ubiquitous in construction, produkcja, wysyłka, and warehousing. They seem simple, but underestimating the forces they endure is a recipe for disaster. Knowing the rated capacity of your hook is non-negotiable, but calculating the actual safe working load (SWL) for a specific lift involves more than just reading the tag. This guide breaks down the essential factors.

Why Calculating Correct Hook Capacity Matters

-

Bezpieczeństwo: The paramount reason. Overloading a hook can lead to catastrophic failure, dropping loads, causing severe injury or death, and damaging property.

-

Legal Compliance: Regulations (Jak OSHA, ASME B30.10) mandate using equipment within its rated capacity.

-

Equipment Longevity: Operating within limits prevents premature wear, odkształcenie, and fatigue failure.

-

Obciążenie: Using equipment beyond its capacity invalidates insurance and exposes you to significant legal liability.

Key Factors in Calculating Safe Hook Capacity

-

1. The Hook’s Rated Capacity (SWL):

- Start Here: Every genuine, properly manufactured lifting hook should have its Working Load Limit (Wll), Bezpieczne obciążenie robocze (SWL), or Rated Capacity clearly marked on it, usually in tons (NAS) or tonnes (Metric). THIS IS THE ABSOLUTE MAXIMUM IT IS DESIGNED TO LIFT UNDER IDEAL CONDITIONS.

- Never Exceed This Marking: This value is determined by the manufacturer based on the hook’s material, projekt, and manufacturing standards (Jak ASME B30.10). It is not a suggestion; it is the legal limit.

-

2. The D/d Ratio (Sling Efficiency):

- The Critical Factor: The hook’s capacity marking assumes the load is suspended by a wire rope or chain sling where the sling body diameter (D) is large enough relative to the hook’s throat opening (D). A small sling on a large hook creates a sharp bend, drastically increasing stress.

- Reguła: The actual load on the hook must be reduced if D/d is less than a specified minimum ratio. Common minimum ratios are:

- ASME B30.10 & Many Manufacturers: Minimum D/d ratio of 3:1 for wire rope slings and 4:1 for chain slings.

- Other Standards/Regions: Minimum D/d ratios can be 5:1 lub wyższy. ALWAYS CHECK THE HOOK MANUFACTURER’S SPECIFIC INSTRUCTIONS AND APPLICABLE LOCAL REGULATIONS.

- The Calculation:

- Measure D (Haczykowe otwarcie gardła) and d (Sling Body Diameter).

- Calculate D/d.

- If D/d is LESS THAN the required minimum (NP., 3:1 for wire rope):

- Reduced SWL = (Actual D/d Ratio / Minimum Required D/d Ratio) x Hook’s Marked SWL

- Przykład: A hook marked for 10 tons SWL. Using a wire rope sling with d = 1 inch. Hook D = 2.5 Cale.

- D/d = 2.5 / 1 = 2.5

- Required Min. Ratio = 3:1 (3)

- Reduced SWL = (2.5 / 3) X 10 tons ≈ 8.33 mnóstwo

- If D/d is equal to or greater than the minimum ratio, the hook’s marked SWL applies (subject to other factors below).

-

3. Sling Angle & Resultant Force:

- The Physics: When slings are used at an angle (not vertical), the force on the hook (and the slings) increases significantly compared to the weight of the load itself.

- The Calculation: The force on each hook (and sling leg) is calculated using:

- Force per Leg = (Load Weight / Number of Legs) / sin(Sling Angle)

- Force on Hook = Force per Leg (for a single hook per sling leg)

- Key Takeaway: As the sling angle decreases (sling gets flatter), the force on the hook INCREASES. You MUST ensure this calculated force does not exceed the hook’s applicable SWL (considering D/d ratio and condition). See our [Guide to Sling Angles] for more detail.

-

4. Center of Gravity (CoG) and Load Dynamics:

- Stabilność: An unstable load or one lifted off-center can create dynamic forces (shock loading, wahadłowy) that impose stresses far exceeding the static weight. These unpredictable forces can easily overload a hook rated for the static load.

- Impact: Even careful lifting involves some initial acceleration. Shock loading from sudden starts/stops or dropping the load onto the hook multiplies the force.

- Mitigation: While not a direct “calculation” on the hook, ensuring the load is balanced, secured, and lifted smoothly is crucial for staying within the hook’s designed capacity. Factor in a safety margin for dynamics.

-

5. Hook Condition & Nosić:

- Critical Inspection: The marked SWL assumes the hook is in new or excellent condition. Regular, thorough inspections are mandatory:

- Odkształcenie: Jakiekolwiek zginanie, pokrętny, or opening of the hook throat.

- Nosić: Reduction in material thickness, especially at the tip or in the saddle (load-bearing area).

- Spękanie: Visible or detectable via NDT (Non-Destructive Testing – Magnetic Particle, Dye Penetrant).

- Korozja: Significant pitting or rust weakening the structure.

- Latch Damage: Jeśli jest wyposażony, a damaged or malfunctioning latch compromises safety.

- Consequence: Any significant wear, odkształcenie, or damage reduces the safe working capacity below the marked SWL. A severely worn or damaged hook must be removed from service immediately. Never guess; inspect rigorously.

Crucial Reminders

-

1. Marking is King (but not the whole story): The marked SWL is the starting point, but it’s only valid under ideal conditions with the correct sling size and no damage.

-

2. D/d Ratio is Paramount: This is the most common reason hooks are inadvertently overloaded. Never ignore it.

-

3. Sling Angles Multiply Force: Low angles are extremely dangerous for hooks and slings.

-

4. Sprawdzać, Sprawdzać, Sprawdzać: A damaged hook rated for 10 tons might fail at 2 mnóstwo. Visual inspection before every use is essential.

-

5. Kiedy masz wątpliwości, DON’T LIFT: If calculations are complex, the hook is questionable, or the load is unstable, stop. Consult a qualified engineer or rigging specialist. Never guess.

-

6. Standardy & Regulations: Always comply with applicable standards (ASME B30.10, OSHA, local codes) and the specific manufacturer’s instructions for your Haczyk dźwigu.

Calculating the safe lifting capacity of a hook is a fundamental responsibility for anyone involved in lifting operations. It’s not simply reading the number stamped on the side. You must rigorously consider the D/d ratio, kąty zawiesia, dynamic forces, the hook’s physical condition, and the stability of the load. Ignoring any of these factors risks catastrophic failure. Prioritize safety above all else: know the limits, inspect thoroughly, calculate correctly, and lift smartly.

Najnowsze komentarze