Crane hooks are vital components in lifting operations, bearing the entire load during hoisting tasks. 時間とともに, due to constant use and heavy loads, クレーンフック are subject to wear and tear. Adhering to crane hook wear limit standards is crucial for maintaining operational safety, preventing equipment failure, and ensuring compliance with international regulations.

The crane hook wear limit standard refers to the allowable degree of material loss on the hook’s critical areas before it must be replaced. These standards are typically defined by organizations like OSHA, asme, ISO, and national regulations, and they help determine when a hook is no longer safe to use.

Here are some widely recognized standards governing crane hook wear limits:

ASME B30.10 (フック):

States that a hook must be removed from service if the throat opening has increased by 5% or more of the original dimension or if there is more than 10% wear on any section of the hook.

ISO 7597:

Establishes uniform tolerances for hook design and recommends specific inspection intervals and replacement guidelines based on wear.

オシャ 1910.179:

While OSHA does not specify wear limits in detail, it requires hooks to be visually inspected daily and thoroughly inspected periodically by a qualified person.

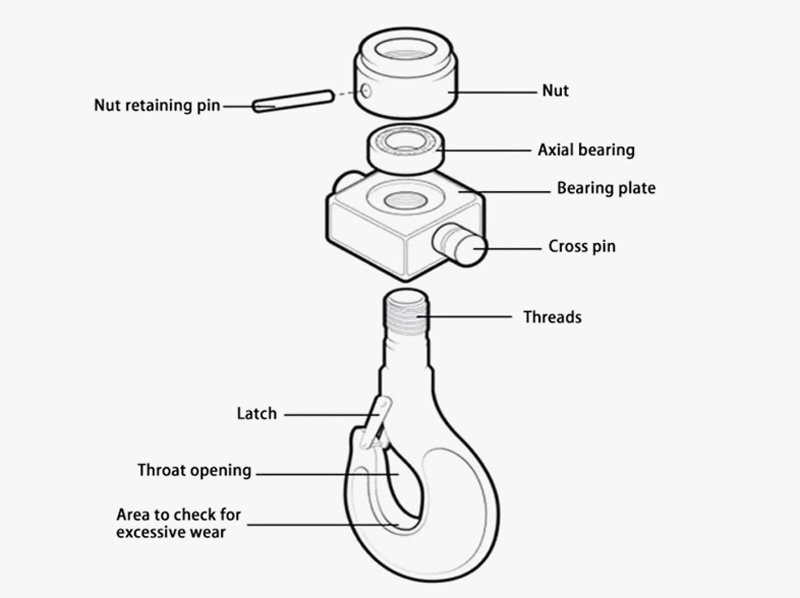

1. Hook Throat (Opening Width)

An increase in the opening can indicate overloading or deformation.

Limit: Do not exceed 5% of the original opening.

2. Hook Saddle (Load-bearing area)

This area experiences the most friction.

Limit: Replace if wear exceeds 10% 元の横断面積の.

3. Latch and Safety Catch

The latch must close completely and operate smoothly. Damaged or missing latches compromise safety.

4. Neck and Eye (Attachment Point)

亀裂を探す, 腐食, or elongation.

1. 毎日の目視チェック:

Done by the operator before use.

2. 定期精密検査:

Conducted by a qualified technician at least every 3 に 12 月, depending on usage frequency and working environment.

Operating with a worn-out crane hook may lead to:

1. Load dropping accidents

2. Equipment damage

3. Serious injury or fatality

4. Legal and financial liability

5. Downtime and repair costs

1. Keep detailed inspection records.

2. Train operators on visual inspection procedures.

3. Use measuring tools like calipers to assess wear accurately.

4. Follow manufacturer recommendations and local regulatory guidelines.

Monitoring crane hook wear is a simple yet critical step toward ensuring lifting safety. Following the crane hook wear limit standard protects not only your equipment but also your personnel and operations. Always inspect regularly, document thoroughly, and replace worn hooks immediately to maintain a safe working environment.

If you’re in need of certified crane hook inspection services or high-quality replacement hooks, contact our support team or visit our products page today.

私たちはあなたのフィードバックを大切にします! あなたの特定のニーズに合わせてサービスを調整できるように、以下のフォームに記入してください.

最新のコメント